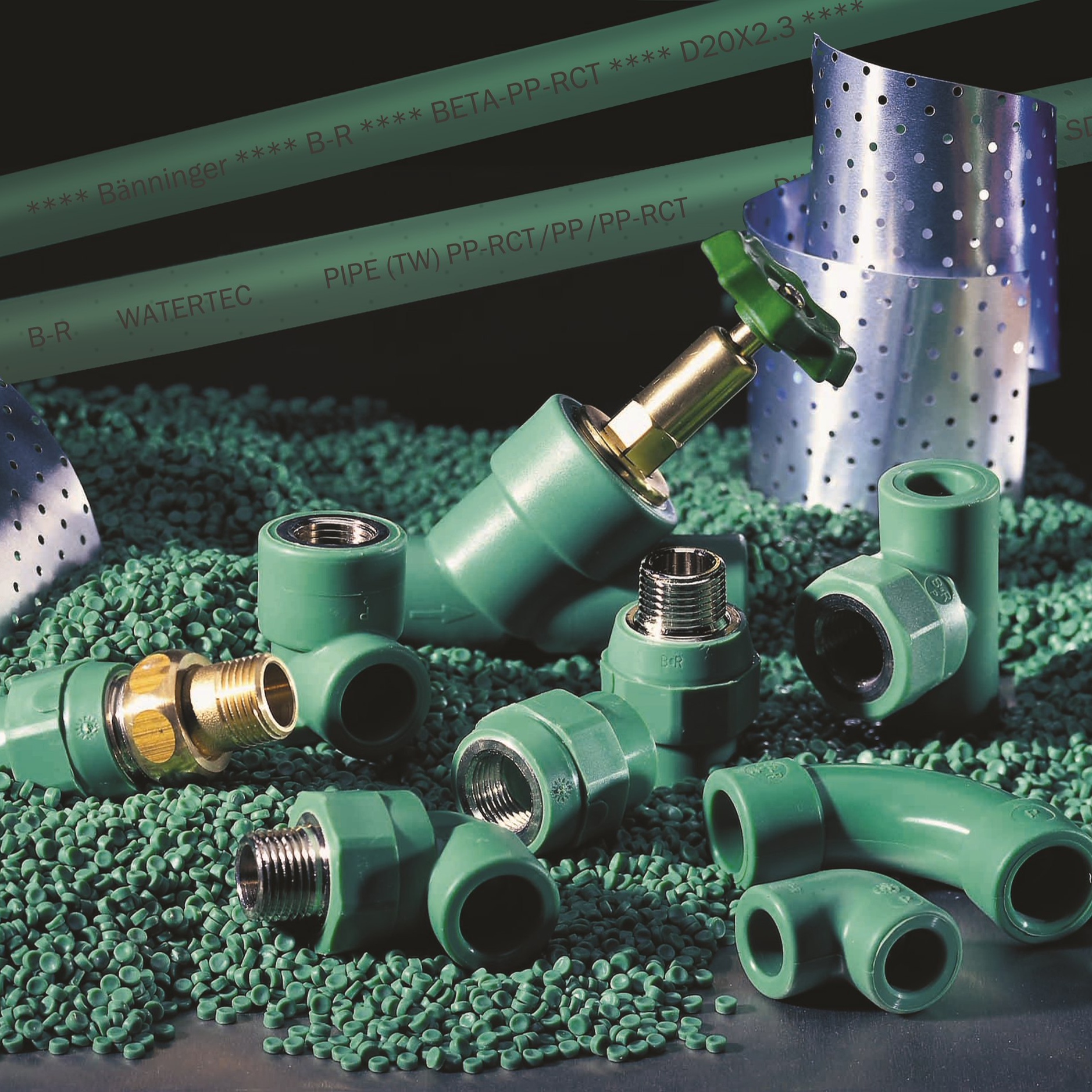

Innovative Manufacturing Processes: PPR (Polypropylene Random Copolymer) fittings have revolutionized plumbing systems with their durability, versatility, and ease of installation. Behind these exceptional fittings lies a world of innovative manufacturing processes. ppr fittings manufacturer employ cutting-edge techniques to mold and shape polypropylene into various fittings like elbows, tees, couplings, and valves. Advanced injection molding and extrusion methods ensure precision and consistency in the production of these fittings, meeting stringent quality standards. With a focus on efficiency and sustainability, manufacturers integrate eco-friendly practices into their processes, minimizing waste and environmental impact.

Quality Assurance and Testing: Ensuring the reliability and longevity of PPR fittings is paramount in the manufacturing process. Rigorous quality assurance measures are implemented at every stage to guarantee the highest standards are met. Manufacturers conduct extensive testing on raw materials to ensure they comply with industry specifications. Throughout production, fittings undergo thorough inspections for dimensional accuracy, structural integrity, and resistance to pressure and temperature extremes. Advanced testing facilities simulate real-world conditions, allowing manufacturers to identify and rectify any defects or inconsistencies before the fittings reach the market. This commitment to quality assurance instills confidence in consumers and reinforces the reputation of PPR fittings for reliability and performance.

Continuous Innovation and Market Adaptation: The landscape of plumbing systems is constantly evolving, driven by technological advancements and changing consumer needs. PPR fittings manufacturers stay at the forefront of this evolution through continuous innovation and market adaptation. Research and development efforts focus on enhancing the design, functionality, and efficiency of fittings to meet the demands of modern plumbing systems. Manufacturers closely monitor market trends and customer feedback to anticipate future requirements and develop innovative solutions. Whether it’s introducing new product variants, improving installation methods, or incorporating smart technology, PPR fittings manufacturers remain agile in responding to the evolving needs of the industry. By embracing innovation and adaptation, they ensure that PPR fittings continue to be the preferred choice for plumbing professionals and consumers alike.