Introduction to Sheeting Machines

Sheeting machines are vital tools in various industries, transforming bulk materials into sheets for easier handling, processing, and packaging. These machines are used in sectors such as food production, textiles, plastics, and construction. They play a crucial role in ensuring efficiency, consistency, and quality in the production process. Understanding the operation, benefits, and types of sheeting machines can help businesses choose the right equipment for their specific needs.

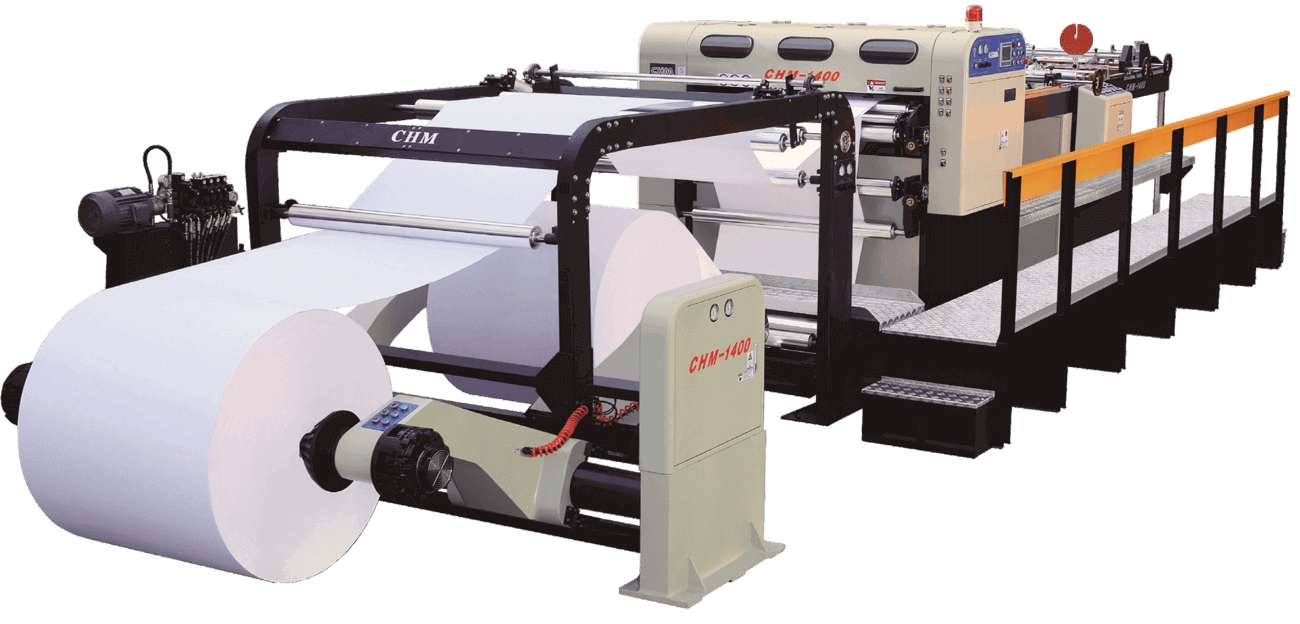

How Sheeting Machines Work

Sheeting machines operate through a straightforward yet effective process. Raw materials are fed into the machine, where they undergo various transformations. The most common mechanism involves rollers that flatten the material into sheets of predetermined thickness. Depending on the material type, additional components, such as cutting blades and temperature controls, may be employed to ensure optimal sheet formation. For instance, in the food industry, heat may be applied to soften materials before sheeting, while in the plastic industry, cooling systems might be necessary to maintain the integrity of the product. The precision of sheeting machines allows manufacturers to achieve uniform thickness, which is essential for product quality and consistency.

Types of Sheeting Machines

There are several types of sheeting machines tailored to meet the diverse needs of different industries. Some of the most common types include:

- Roller Sheeters: These machines use rollers to flatten materials into sheets, ideal for dough, plastic, and rubber processing.

- Sheet Extruders: Commonly used in the plastic industry, these machines extrude molten material through a die to create sheets.

- Multi-roller Sheeters: Utilizing multiple rollers, these machines are designed for high-volume production, providing greater speed and efficiency.

- Thermoforming Sheeters: These machines heat plastic sheets before molding them into specific shapes, commonly used in packaging and container production.

Each type of sheeting machine has its unique features and capabilities, making it essential for manufacturers to choose the right machine based on their material, production volume, and desired sheet characteristics.

Advantages of Using Sheeting Machines

Investing in a sheeting machine offers numerous advantages to businesses across various sectors. Here are some key benefits:

- Increased Efficiency: Sheeting machines streamline the production process, reducing manual labor and minimizing waste. Automated sheeting processes enable faster production rates compared to traditional methods.

- Consistent Quality: The precision of sheeting machines ensures that each sheet produced meets specific thickness and quality standards. This consistency is crucial for industries like food packaging, where uniformity is vital.

- Versatility: Sheeting machines can handle a wide range of materials, making them adaptable to different production needs. This versatility allows businesses to switch between products without significant downtime.

- Cost Savings: By increasing efficiency and reducing waste, sheeting machines can lead to substantial cost savings over time. Additionally, their ability to produce high-quality sheets can enhance product marketability, driving sales.

In conclusion, sheeting machines are indispensable tools in modern manufacturing, enabling businesses to produce high-quality sheets efficiently and consistently. Understanding how these machines work, the different types available, and their benefits can empower manufacturers to make informed decisions and enhance their production processes.